Fire protection solutions for warehouses and logistics centres

Fire prevention, detection and suppression in warehouses

WAGNER offers operators of warehouses and logistics centres innovative fire protection concepts that ensure operational safety and help protect people, processes and products: the OxyReduct® active fire protection system reduces oxygen concentration levels within a previously defined protected area, preventively inhibiting fires from developing or spreading. Unlike sprinkler-based fire protection, oxygen reduction prevents fires from starting in the first place.

WAGNER’s highly sensitive TITANUS® air sampling smoke detector (previously known as aspirating smoke detector) can detect fires with 2,000 times more sensitivity than conventional smoke detectors, thus providing a crucial head start in the event of fire. Despite their high sensitivity, these air sampling smoke detectors are extraordinarily safe from false alarms, thanks to built-in filters, LOGIC∙SENS intelligent signal processing, and drift compensation.

FirExting® gas extinguishing technology is WAGNER’s contribution to the field of fire suppression. These automatic gas extinguishing systems use inert gases (nitrogen, argon, CO2) to suppress fires. The advantages these extinguishing agents offer are that they are efficient and leave no residue. Goods remain free from the water damage that frequently results from extinguishing with conventional sprinkler systems, so processes can be resumed immediately.

Planning fire protection for warehouses and logistics centres

Planning storage buildings—regardless of whether they are new structures, building conversions, or expansion constructions—requires taking a variety of fire protection-related regulations and legal guidelines into account. Requirements as regards fire protection primarily stem from building laws. These governmental specifications should only be seen as minimum requirements, however, and only cover a limited number of protection objectives. Additional measures are often necessary in order to fulfil insurance company requirements regarding fire protection. Generally speaking, these additional measures are also necessary in order to achieve additional protection objectives, such as property protection or road-safety obligations. The individual operator’s requirements regarding fire protection also play a role when it comes to planning fire protection measures. For example, an operator may elect to put more extensive fire protection measures into place for reasons of personal responsibility, safeguarding, or ensuring operational processes. In summary, the following requirements must be taken into account when planning fire protection systems:

- Building law-related regulations

- Insurance company requirements

- Operator requirements

However, companies come in a wide range of sizes and have a wide range of needs, which makes it impossible to create a single, generally applicable model for determining the necessary fire protection measures. As such, it is important to involve a fire protection expert in the planning stages of warehouse and logistics centre construction projects, so that he or she can create a fire protection concept tailored to the individual needs of that project.

Why WAGNER?

As experienced systems engineers, WAGNER specialises in planning and designing fire prevention systems for warehouses and logistics centres. The company numbers among the global technology leaders in the fire prevention sector.

Not convinced yet?

Find out more! Feel free to contact

us here

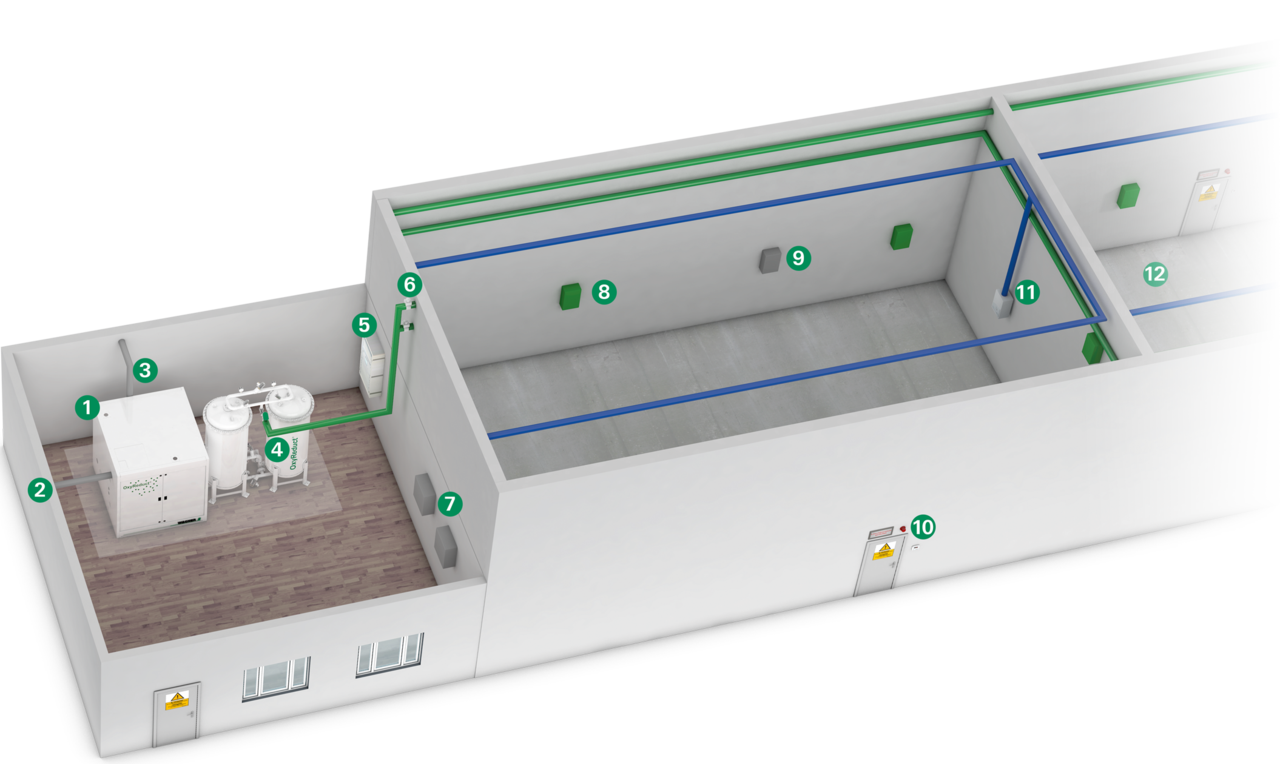

1 OxyReduct® generator (VPSA technology): Extracts nitrogen from room air on location and uses it to reduce oxygen concentration levels within the protected area

2 Supply air (room air)

3 Exhaust air (O2)

4 N2 infeed pipe: Feeds nitrogen into the protected area, where it is generally distributed via an air recirculation system

5 OxyControl central controller: Manages processes for the entire OxyReduct® system

d6 Selector valve: Opens/closes nitrogen supply valves for specific areas

7 Area regulator 1 and 2: Work together with OxyControl to monitor oxygen content and adjust it to within defined protection levels

8 OXY-SENS® O2 Sensor: Continuously measures oxygen concentration levels within the protected area

9 OXY-SENS® SIL2 Sensor: Provides supplementary oxygen concentration measurements and activates sector valve closure when they drop below 12% vol.

10 Area display: Shows the current oxygen concentration levels within any given protected area

11 TITANUS® air sampling smoke detector: Active fire detection using air sampling to identify smoke early on

12 Needs-appropriate protection concepts: Multiple protection schemes and oxygen concentration levels may be employed in order to keep protected areas accessible, e.g., unrestricted access for personnel or restricted access for maintenance purposes

Combining systems

VisuLAN® risk management makes it possible to monitor and manage a variety of building technology, communications, and security systems centrally. This minimises security risks and operating errors, and makes it possible to take appropriate emergency response action quickly, in order to prevent more serious damage.